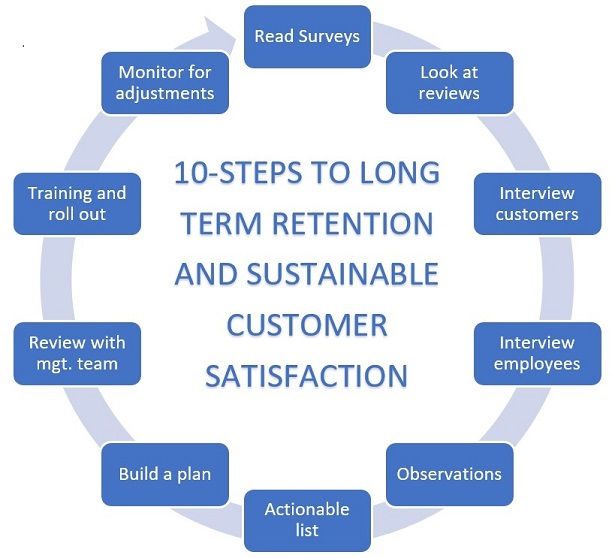

I have created dynamic change in many dealers that takes effect quickly and is very sustainable. Here are the steps that I use. This process has been effective on small dealers to some of the largest in the nation. This 5-minute read is worth your time.

1. Surveys – Reading the last 120 days of negative surveys and documenting the issues that created poor customer experience. For smaller dealers that have a low count, you may need to go back 6 months. This step will highlight any issues that are repeating themselves.

2. Google / Dealer Rater / Yelp Reviews – Reading the posts will let you know the customers' thoughts that they will not say to your face. A valuable tool if used correctly.

3. Interviewing Customers – In Sales: While someone is waiting for F&I ask them about the process. Shopping online, email/text communication, calling in, arrival, did they have an appointment? Also, the sales process, and the time they spent in each step. What made you better/worse than other dealers they may have shopped with? In Service: Take the time to talk to your customers in the lounge, wait for a shuttle, before or after paying at the cashier, and waiting for their vehicle after the service is complete.

4. Interviewing Employees – Ask your employees what could be done to make the processes work more efficiently and better assist the customer and help them with their job. Sales department interviews speak to Sales Managers, F&I Managers, Porters, and Salespeople. In the service interviews sit down with: Porters, Car Wash personnel, Techs, Parts front and back counter staff, Shuttle Drivers, Cashiers, and Advisors to find out the processes from their perspective. Keeping in mind only those that are involved in the process that needs improvement.

a. Customer Facing Staff – The customer-facing staff ask them how things can be improved, ask them what they do in each step, and then later in the observation stage you will see if they do versus what they say they do or if they are just letting you know what the process is they were trained to do.

b. Behind the Scenes Staff – Sales Valets, Porters, Tech, Car Wash, … Are more valuable than you can ever believe, have great ideas and work harder if they feel as if they can make a difference and are part of the team.

c. Follow-up Staff – Talking to those who do your follow-up is combining VoC and VoE. This follow-up staff will add to understanding what the customers think and possibly find customers that you can speak to that will have the feedback needed to develop your dealership's improvement plan.

5. Observations – For sales watch the ups and process the salespeople take, up the count, CRM, phones by listing to recordings if you have this on your phones, negotiation, and the time frame, desking and the time it takes, the same for F&I, and the delivery. In service watch the service drive, dispatch, MPI, status call, repair, wash, cashiering, and delivery porters. This visual will paint a picture that allows you to see if what you believe is truly happening and is getting done in the fashion it was designed to do or NOT!

6. Actionable List – Once you have gone through this extensive process of discovery then take a step back and look at the different items that need addressing. Some are easy changes and are the low-hanging fruit, and some may be more difficult and may need to be addressed over time. Biting off too much at once is a recipe for disaster.

7. Build A Plan – With what you have found in discovery and organized it in making an actionable list, now it is time to lay out how and what timeline to act on the task(s) at hand. First, bullet points each task with the purpose, advantage, and end result of completing this improvement. Then set up the steps and timeline of the improvement at hand.

8. Review with Management Team – Set aside enough time to go over this with that department's management team. Let them know you are not looking for “yes-men” (people), you want constructive criticism and make changes as needed. This process is very important if the management team is not involved and onboard then it will not take hold and will fail.

9. Training and Roll-Out – Bring in the entire section of the team where the improvement is to be made for an explanation of the task and rollout. You may need more micro-meetings or one-on-ones to provide for most effective training.

10. Monitor For Adjustments – Tasking your management team to monitor their departments to make sure the processes are working. Observations and interviews of staff are a great way to see if it is occurring and minor adjustments that could be made. The front-line staff helps you find items you could never see.

Comments